Comparison of Linear Drive Technologies Linear Motor Screw Drive Tooth Belt Piezo Pneumatic Systems

Which linear drive technology offers the best combination of precision, efficiency, and long term durability?

A direct comparison of linear motors, screw drives, tooth belts, piezo systems, and pneumatic actuators.

Linear Motor Screw Drive Tooth Belt Piezo and Pneumatic Systems in Direct Comparison

In modern automation, linear motion must be precise, energy efficient, and reliably stable. Five core drive technologies are available: linear motors, piezo drives, screw drives, tooth belts, and pneumatic systems.

This page provides a direct technical comparison of all five drive types based on eight key performance criteria. The evaluation is grounded in measurable characteristics, practical industrial applications, and extensive engineering experience.

The aim: to identify the optimal technology for precise, dynamic, and long lasting linear motion.

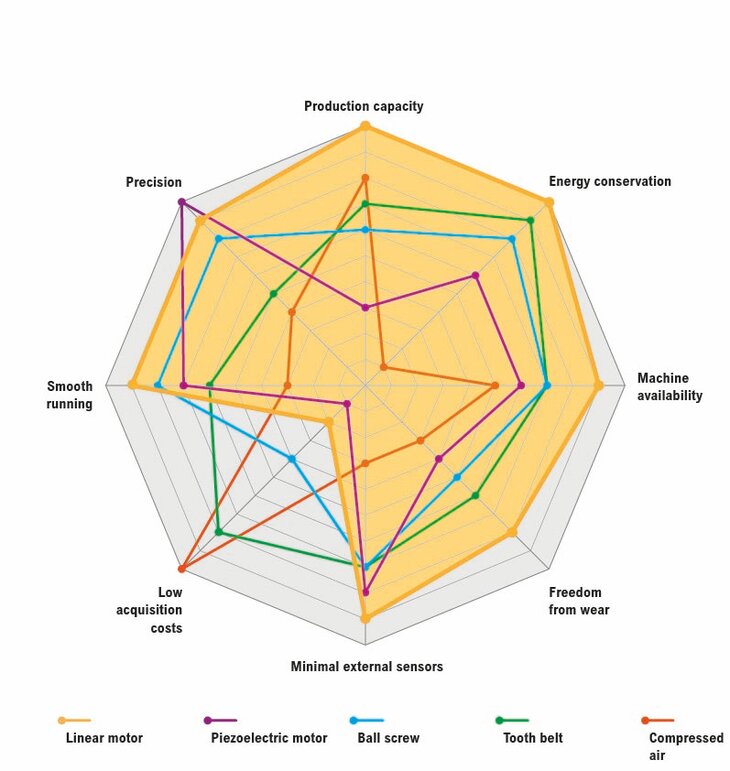

Comparison Across Eight Key Criteria

To make the differences between the five drive types clear, each technology was assessed against eight key technical criteria. The ratings are based on measurable performance characteristics, industrial experience, and typical application requirements.

Linear Motor

Direct, precise, and nearly maintenance free. The linear motor operates without mechanical transmission and achieves maximum repeatability with minimal wear. With direct force transmission, it delivers maximum dynamics, very smooth motion, and consistently high machine uptime.

Advantages: highest precision, high energy efficiency, minimal wear, smooth operation

Piezo Drive

Extremely precise and ideal for micro movements, but strongly limited in stroke, dynamics, and force. Piezo drives are suitable for laboratory, optical, and measurement applications, but they cannot achieve industrial cycle rates and are not designed for long travel distances or high loads.

Advantages: highest precision, very low energy consumption, smooth operation

Limitations: short stroke, low force, high cost, limited production capacity

Screw Drive

Proven technology with simple mechanics, but prone to wear and maintenance intensive. Screw drives are suitable for light to medium positioning tasks, but friction, backlash, and limited speed significantly restrict performance. They are less suited for high dynamics, long service life, and sustained precision.

Advantages: low acquisition cost, solid force transmission, simple integration

Limitations: backlash, wear, lubrication requirement, limited dynamics

Toothed Belt Drive

Cost effective, lightweight, and ideal for long travel distances under moderate requirements. Toothed belt drives offer high speed at low cost, but are limited in precision, stiffness, and long term stability. Belt stretch and temperature sensitivity reduce repeatability, making them less suitable for demanding industrial applications.

Advantages: very low acquisition cost, high speed, long travel ranges

Limitations: low precision, limited stiffness, belt stretch, reduced long term stability

Pneumatic Drive

Fast and inexpensive, but energy-intensive, noisy, and difficult to control precisely.

Suitable only for simple on/off movements – not for demanding automation tasks requiring precision or dynamic motion profiles.

Advantages: low acquisition cost, simple integration, fast basic motion

Limitations: high energy consumption, low precision, noise, limited controllability

Conclusion: Why the Linear Motor Prevails

The linear motor delivers the best overall combination of precision, dynamics, energy efficiency, and machine uptime.

With no mechanical transmission and minimal wear, it achieves maximum repeatability even at high cycle rates.

This makes it the most sustainable and high-performance technology for modern automation.

Jenny Science consistently relies on direct drives to ensure the highest precision, best dynamics, and most reliable production processes over the long term.

→ View LINAX® Linear Motor Axes