The Future of Precision Motion Control

Jenny Science develops and manufactures compact direct drives engineered for maximum precision and dynamic motion.

Swiss Engineering in Motion – designed for automation systems where every millimeter counts.

Your Advantages with Jenny Science

Compact Design. Fast Motion.

Compact Design. Fast Motion.

More performance in minimal space.Our linear motor axes combine highest precision and maximum dynamics in the smallest installation area.

Thanks to their compact design and low moving mass, they achieve accelerations above 10 g and speeds up to 4 m/s – ideal for short cycle times, compact machines and high-precision automation.

Your Advantages

-

Save space – minimal installation volume for maximum freedom in machine and cabinet design

-

Reduce cycle times – high dynamics with low moving mass

-

Increase precision – reproducible accuracy with every stroke

-

Improve energy efficiency – optimized system design with highest efficiency

Learn more about linear motor axes

From Single Axis to Complete System – in Minutes.

Modular. Standardized. Ready to use.

With just a few steps, individual axes can be combined into a complete pick & place system, gantry, or cross table.

Standardized interfaces such as EtherCAT, PROFINET, or Ethernet/IP ensure full compatibility.

Commissioning is performed directly in the web browser – no software installation required.

Your Advantages

- Build complete Pick & Place systems, gantries, or cross tables within minutes

- Fully compatible with EtherCAT, PROFINET, and Ethernet/IP

- Plug in, connect, and start – directly via web browser, no software required

- Precise, maintenance-free, and ready to mount immediately

Maintenance-Free Direct Drives with Integrated Forceteq® Force Measurement

Maximum machine uptime. Zero downtime.

Up to 350 million cycles without maintenance – thanks to the integrated Forceteq® force measurement inside the drive.

Processes are continuously monitored in real time, and deviations are detected instantly – ensuring consistent quality and maximum service life of your system.

The Forceteq® technology from Jenny Science enables precise force measurement directly inside the servo drive – without external sensors.

Ideal for automated testing, joining and assembly processes.

Your Advantages

- Reduce maintenance costs by up to 30 %

- Maximize machine availability with zero downtime

- Ensure real-time quality control through integrated Forceteq® force measurement

Learn more about Forceteq® real-time force measurement

Ready to optimize precision and efficiency in your automation?

Talk to our motion experts

Our Products – Solutions at a Glance

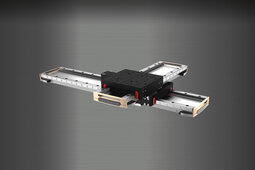

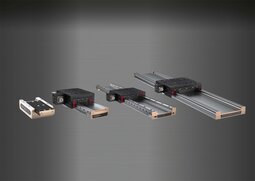

LINAX® Linear Motor Axes

Compact. Precise. Dynamic.

The LINAX® linear motor axes deliver maximum dynamics and high precision in the most compact design.

With their minimal installation height and robust linear guidance, they are ideal for applications with limited space – from single-axis setups to complete cross tables.

Designed for laboratory automation, test benches, handling systems, and special machinery – wherever high dynamics and compact size are required.

Key Advantages

- Minimal space requirement – installation height starting from just 25 mm, ideal for tight design environments

- High stiffness – wide guide rails ensure stability even for travel distances up to 1.6 m

- Versatile in use – carriage can be mounted on top or bottom, ideal for compact cross-table and pick & place systems

Learn more about LINAX® linear motor axes

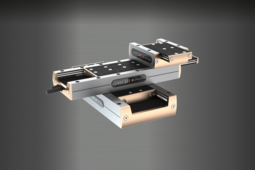

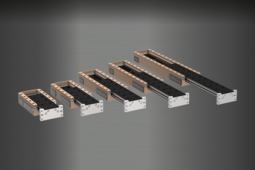

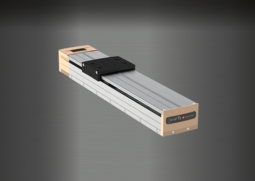

ELAX® Linear Motor Slides

Modular. Dynamic. Effortlessly Connected.

The compact ELAX® linear motor slides are the perfect solution for fast and precise pick & place applications in tight spaces.

With their modular design and one-cable technology, individual axes can be combined within seconds into complete multi-axis systems – precise, maintenance-free and immediately ready for operation.

Typical areas of application include assembly and testing processes, laboratory automation, mounting and packaging systems where precision and short cycle times are essential.

Key Advantages

- Integrated axis modules – modular setup allows directly screw-mountable multi-axis combinations

- High dynamics – optimized for fast pick & place motions with outstanding repeatability

- One-cable technology – only one connection per axis for simplified wiring and maximum system clarity

Learn more about ELAX® linear motor slides

ROTAX® Hollow Shaft Rotary Motors

Compact. Powerful. Direct Drive.

The ROTAX® hollow shaft rotary motors combine high torque with a compact, space-saving design.

Their large hollow shaft allows cables, lines, or media to be routed directly through the axis – ideal for robotics, handling, testing, and advanced automation systems.

Key Advantages

- Flat design & large hollow shaft – only 50 mm installation height; cables or media can be routed directly through the axis

- Direct drive power – high torque without gearboxes for dynamic, wear-free motion

- Ready to run – integrated absolute system, immediately operational without homing; one-cable technology for effortless installation

Learn more about ROTAX® hollow shaft rotary motors

INTAX® – Integrated Linear Axis

All in one. Ready to run.

The INTAX® integrated linear axis is the world’s first axis with a fully integrated servo controller.

Motor, electronics, and cabling are combined in a compact housing, delivering maximum performance with minimal installation effort.

Ideal for compact automation systems, laboratory setups, and machine integration where space, simplicity, and precision are essential.

Key Advantages

- All-in-one design – motor, controller, and cabling combined; no external hardware required

- Integrated absolute system – immediately operational after power-on, no homing needed

- Fully network-ready – compatible with EtherCAT, Ethernet/IP, and PROFINET for seamless PLC integration

Learn more about INTAX® integrated linear axes

XENAX® Servo Controller

Universal. Connected. Intuitively Controlled.

The XENAX® servo controllers form the central motion control platform for all Jenny Science linear and rotary axes.

With an integrated web interface and automatic axis detection, they enable fast commissioning, precise motion, and safe operation – all without any software installation.

Key Advantages

- Flexible integration – compatible with all Jenny Science linear and rotary axes

- Web-based interface – integrated HTML5 web server (WebMotion® GUI) for quick setup and diagnostics directly in the browser

- Smart & safe – automatic motor detection, PLC libraries, and TÜV-certified safety functions integrated

Learn more about XENAX® servo controllers

FORCETEQ® Force Measurement Technology

Measure. Monitor. Control – in real time.

The Forceteq® technology enables patented force-displacement measurement directly inside the servo controller.

Forces and movements are monitored with micrometer precision during the process – completely without external sensors.

The result: maximum process reliability and documented quality in real time.

Key Advantages

- Real-time quality control – measures forces during the production process and records force-displacement diagrams; deviations are detected instantly

- No external sensors required – force measurement integrated directly in the servo controller; no additional hardware needed

- Optimized for critical applications – ideal for joining, press-fit, and precision assembly processes requiring immediate real-time feedback

Discover Forceteq® force measurement technology

We are happy to advise you on the ideal solution for your application.

Contact us now

Global leaders trust our precision.

Our customers include top companies in medical technology, machine building, and industrial automation, relying on Swiss engineering for motion control excellence.

What Our Customers Say

“The compact high-end drives from Jenny Science fit perfectly into our high-performance systems.

Thanks to their fast delivery times, we were able to realize projects without delays and truly appreciate the direct, straightforward communication with their team.”

Fabian Stutz, CEO and Co-Founder, Pharmabotix AG

https://pharmabotix.ch

“Our partnership with Jenny Science has existed since 2008 – and during this time, we have successfully implemented numerous projects together.

We particularly value their high flexibility, which enables us to win new customers every day.

The continuous development of their products shows that innovation and quality at Jenny Science are not just goals, but true passion.”

Steve Aeby, Sales Manager and Co-Owner, Axnum AG

https://www.axnum.ch

"We consider Jenny Science not just a supplier, but a true development partner in our pursuit of furthering precision automation. Through our collaboration efforts, we’ve refined our force-control capabilities and achieved highly precise results. Our partnership with Jenny Science has always been one of trust and efficiency, regardless of distance."

Nathan Passmore, Engineering Manager, Lanco Integrated

https://lancointegrated.com/

FAQ – Frequently Asked Questions

Here you will find answers to the most common questions.

If you would like to know more, our team will be happy to advise you personally.

Thanks to the intuitive WebMotion® interface via browser, your axis is operational in less than five minutes – completely without software installation.

Yes. Thanks to stand-alone operation, stored programs, or I/O control, the axes can be operated independently – ideal for simple pick & place applications.

Yes. Forceteq® Basic measures forces directly via motor current – no external sensor required.

Ideal for assembly or testing processes.

Yes. With Signateq®, strain gauge sensors (DMS) can be connected directly to the XENAX® controller, enabling precise control based on force or torque.

EtherCAT®, PROFINET®, EtherNet/IP®, CANopen®, and POWERLINK® – ensuring full compatibility with Siemens, Beckhoff, B&R, Rockwell, and many more.

Yes. The fast trigger function in the FPGA reacts in under 250 nanoseconds – perfect for line scan cameras, lasers, or inline inspection systems, where real-time precision is crucial.

They achieve a repeatability of ±0.4 µm and speeds up to 4 m/s – ideal for applications requiring maximum dynamics and precision.

With LINAX® Lxs shuttle axes, you can build gantry systems quickly and robustly.

Special mounting brackets with rotation and length compensation prevent mechanical stress – ensuring precise, backlash-free motion and maximum dynamics over time.

With the integrated SMU (Safety Motion Unit): STO, SS1, SS2, and SLS – TÜV-certified according to the EU Machinery Directive.

Whether you need consulting, have a technical question, or are looking for an customized solution – we are happy to support you.

Do you have a specific question or need personal advice?