Frequently Asked Questions (FAQ)

Increase your linear motor know-how about precision, dynamics and forces. Fast online

support all over the world.

1. Web-Browser no connection, Tips and Tricks?

2. Optimize the closed loop parameters?

3. Firmware-/ WebMotion® Update?

4. Which precision do the linear motor axis offer?

5. Maximum Speed / Acceleration / Force for the LINAX® / ELAX®

6. What load can the linear motor axes move?

7. What is to consider when using a linear motor axis vertically?

8. Which cable variants are aviable for the different linear motor axis?

9. What kind of maintenance is recommended for the linear motor axis?

10. How can I calculate the required power supply?

11. Does the position detection remain after switching the XENAX® Xvi on and off?

12. When is a SMU necessary and are there any alternatives?

13. Can I install the optional modules (Fieldbus / SMU) by myself?

14. Which linear motor axes support Forceteq®?

15. What force accuracy can I excpect with Forceteq® without an external force sensor?

16. How do I use Forceteq® with a PLC?

17. Can I control a LINAX®, ELAX® or a ROTAX® with a "third party" controller?

18. Magnetic effect of the linear motor axes?

1. Web-Browser no connection, Tips and Tricks

By default, the XENAX® servo controllers are delivered with the IP address 192.168.2.100. The subnet mask is set to 255.255.240.0. This means that the tablet / laptop / PC needs to be in an IP address range of 192.168. "0-15". "0-255" n order to make a first connection. Adjustable under "Control Panel \ Network and Internet \ Network and Sharing Center" Change adapter settings / then customize the desired connection with right-click properties in the IP protocol TCP / Ipv4. The connection can be checked with the cmd.exe and the command Ping + "IP-Adresse". As soon as the connection is established, the IP address and subnet mask of the XENAX® servo controller can be changed to any address using XENAX® Ethernet Installer.

Important note: The WebMotion® on the XENAX® Xvi 75V8 is based on JAVA. The newer XENAX® Xvi 48V8 is based on HTML5. Since various browsers no longer support JAVA, we offer the encapsulated QupZilla Webbrowser with integrated JAVA. The HTML5 version of WebMotion® works on all leading browsers like Firefox, Google Chrome, IE, Microsoft Edge etc.

Error Port 10001 refused

This error means that a connection to the XENAX® Xvi already exists. This happens when the browser tries to open the same XENAX® Xvi IP address a second time. (multiple tabs)

2. Optimize the closed loop parameters

The XENAX® Xvi servo controllers automatically recognize each LINAX®, ELAX® or ROTAX® and the basic parameters will be set automatically. After the successful referencing drive, the fine tuning can be started.

WebMotion® «setup»– «state controller» Closed Loop settings.

1. Set the «Payload»

2.Click «Auto Gain»

WebMotion® «move axis» - «by click» start a continuous drive between two positions with the desired speed.

1. Set «SPEED» and «ACC x1’000»

2. Set a Wait Time «Wait Reverse» of 200ms between the movement

3. «Go Position (Absolut)»

4. Start the relative movement with «Rep Reverse».

WebMotion® «move axis» - «motion diagram» record the movement.

1. «record new»

2. Select «DEVIATION»

Monitor the target position:

An undershoot (in the example -47 inc) before reaching the target position. This means that the «payload» is too small / not set. Increase the «payload» and repeat the measurement. (Target position 40'000 inc.)

An overshoot (in the example +25 inc) before reaching the target position. This means that the «payload» is to high. Reduce the payload and repeat the measurement (target position 40'000 inc)

After this adjustement the «Gain Pos» can be increased under «setup» - «state controller». This as long as the linear motor axis remains quiet and does not vibrate or oscillate. If you have a multi-axis system, the system usually oscillates earlier by mutual influence of the axes.

Procedure for oscillating axis:

1. Move the linear motor back and forth between the positions in which it is swinging.

Note: With a slow ride, these positions are usually easier to find (eg "move axis" - "by click" set "SP OVERRIDE" to 20%)

2. Under «setup» - «state controller» on «F Setting» click on «F Analysis» to determine the oscillation frequency

3. With «F Setting» the frequency will be filtered

4. If it still vibrates, repeat the analysis again. If the second frequency is half the original frequency set it.

5. At further vibration, reduce «Gain Pos».

For further information please do not hesitate to contact our support.

3. Firmware-/ WebMotion® Update?

With our XENAX® Ethernet Installer it is easy to handle a firmware / WebMotion® update or to change the IP adress and back up the application.

Up to 15 XENAX® Xvi serco controllers can be controlled simultaneously.

4. Which precision do the linear motor axis offer?

LINAX® Lxc, no cable moving:

Repeatability bidirectional, steady temperature

- Optical scale 100 nm: ±0.4 µm

- Optical scale 1 µm: ±1.5 µm

LINAX® Lxs, Lxu, Lxe cable on move:

Repeatability bidirectional, steady temperature

- Optical scale 100 nm: ±0.5 µm

- Optical scale 1 µm: ±2 µm

- Magnetic scale 1 µm: ±5 µm (Magnetic scale available with Lxs/Lxu)

ELAX® Ex

Repeatability bidirectional, steady temperature

- Magnetic scale 1 µm: ±5 µm

ROTAX® Rxvp (Vakuum/Compressed Air Feedthrough)

Repeatability bidirectional, steady temperature

- Magnetic round scale 64'000 Inc/Rev. ±0.006° / ±20ws

- corresponds ±0.5µm with a radius of 10mm

ROTAX® Rxhq (High Torque)

Repeatability bidirectional, steady temperature

- Magnetic round scale 120'000 Inc/Rev. ±0.004° / ±12ws

- corresponds ±0.3µm with a radius of 10mm

Absolute bidirectional accuracy:

The absolute accuracy is variable from the position measuring point with the distance to the measuring head. The mechanical precision of the linear axis is depending on roll, pitch and yaw.The absolute accuracy can only be measured specifically for a measuring point on the mechanical structure. We can perform such measurements with our laser interferometer.

The linear scales have a temperature-dependent length variation which influences the travel path.

- optical scale: 0,85 µm per degree °C and 100 mm

- magnetic scale: 1,1 µm per degree °C and 100 mm

Further information can be found in our datasheet LINAX® construction series (PDF) or

ELAX Ex F20 (PDF).

5. Maximum Speed / Acceleration / Force for the LINAX® / ELAX®

Our linear motor axes are designed for a maximum speed of 4 m / s. We can calculate your maximum speed with your Payload on our "Cycle Calculator" for you. Contact us now.

The nominal force of our motors can be found in the name

For Example: LINAX® Lxs 400F60

The "....F60" corresponds tot he nominal Force of 60 N.

The peak force is three times the nominal force, in this case 180N.

Maximum force= 180 N

The acceleration «a» is calculated from -> F=m*a -> a=F/m

Example mPayload = 1500 g, mSlider = 950 g,

m = mSlider + mPayload = 2.45 kg

Maximum acceleration a = Fp / m = 180 N / 2.45 kg = 73.5 m/s2 --> 73.5 / 9.81 = 7.5 g

Note for Running Time:

At the nominal force the running time is 100%. For the peak force the current is three times higher. The power loss increases quadratically. PV = I2 * R. The power loss when using the peak power is 9 times greater. Consequently, the peak power can only be used during 1/9 of the running time --> 11%.

6. What load can the linear motor axes move?

In a Horizontal application the load is moved with the driving force of the linear motor. A reasonable approach is to select the linear motor type so that the maximum load still allows an acceleration of 1g = 9.81m/s2 as in free fall, then gives a medium dynamic.

The corresponding load can be very easily calculated from the axis identifier. We use the peak force for the acceleration, which is 3 times higher than the nominal force in our linear motors.

|

Linear motortyp |

Nominal force |

Peak force F |

Payload medium Dynamic |

|

LINAX® Lxc 44F08 |

8 |

24 |

m = 2.45 – 0.13 = 2.32 |

|

LINAX® Lxc 176F40 |

40 |

114 |

m = 11.62 – 0.75 = 10.87 |

|

LINAX® Lxs 520F60 |

60 |

180 |

m = 18.35 – 1.00 = 17.35 |

|

ELAX® Ex 50F20 |

20 |

60 |

m = 6.12 – 0.26 = 5.86 |

Even higher payloads can be moved thereby reducing acceleration and speed and the movement takes longer. In this case, an acceleration of ½ g should still be achieved, this maximum load is twice the above calculated payloads.

- The goal is always to have a low payload as possible, a filigree construction and parts with little mass would be the best.

The mechanical guides are designed for much larger load forces than the linear motor can move. This means that vertical joining or press-fitting processes are easily possible. These maximum load forces can be found under "Stress Values of Guides Lxc" in the document LINAX® construction series (PDF) or ELAX® Ex F20 (PDF).

7. What is to consider when using a linear motor axis vertically?

If the linear motor axis is used vertically, the slider should not fall when the power is switched off. An adjustable weight compensation for different axe types are available.

|

Linear motor type (samples) |

Cmpensation technology |

Range of payload [kg] |

|

LINAX® Lxc 44F08 |

Compressed air |

Up to 3kg |

|

LINAX® Lxc 85F10 |

Compressed Air |

Up to 3kg |

|

LINAX® Lxc xxxF40 |

Compressed Air |

Up to 6kg |

|

LINAX® Lxu xxxF60 |

Compressed Air |

Up to 6kg |

|

ELAX® Ex xxxF20 |

Several spring packages |

Up to 2kg |

8. Which cable are available for the different linear motor axis?

LINAX linear motor axes:

The LINAX® linear motor axes require a motor and an encoder cable. These can be ordered in the following variants. The length of each cable can be selected (Max. Total length 20m)

Option 1: Standard connecting cable

Use in stand-alone applications, in which the cables are little or not in move.

Option 2: Connecting cable for extension with extension cable

Option 3: Connection cable for extension with intermediary cable and extension cable

Used for applications with energy chains to separate the cables before and after the energy chain. The use of several intermediary cable is possible.

ELAX® linear motor slide and ROTAX® rotary axis:

Both have a single-cable solution that combines motor and encoder cables. The same three options as shown in the LINAX® are possible. For option 3, a maximum of one intermediary cable can be used due the special EMV protection.

9. What kind of maintenance is recommended for the linear motor axes

The most important maintenance is the lubrication of the bearing guides. To lubricate all linear motor axes easily we recommend using the dosage pistol with the lubricating cartridge.

Ball bearing guides (LINAX® Lxu, Lxs, Lxe)

Refill the lubrication pad every 5'000 km. Typically this is done during semi-annual or annual maintenance of the machine.

155.00.10 VA Dosage pistol for lubrication

155.00.11 VA Cartridge with standard lubricant

Cross roller guides (LINAX® Lxc and ELAX® Ex)

Annually lubrication of the guiding sticks.

155.00.10 VA Dosage pistol for lubrication

155.00.11 VA Cartridge with standard lubricant

10. How can I calculate the required power supply?

The XENAX® Xvi servo controllers can be supplied separately for logic and power.

- Logic: 24 V + 0.3 A per Axis

- Power: 24 – 75V 5 A + 3 A per additional Axis.

The linear motor axis reaches their peak force already with 24V power. If the LINAX® Lxu and Lxs are used in a high dynamic they will need a higher power supply:

Dynamic > 1 m/s = 48 V and Dynamic > 2.5 m/s = 75V.

This is because of the back EMF

11. Does the position detection remain after switching the XENAX® Xvi on and off?

As long as the logic is switched on, the position detection remains.

Every time the logic is restarted, a reference run is necessary.

The LINAX® linear motor axes move over 2 reference marks (maximum distance 20mm).

The ELAX® linear motor slides move to the internal mechanical stop (extended or retracted), the internal mechanical stop is calibrated in our assembly before delivery. An external mechanical stop can also be used for referencing further information on this can be found in the XENAX® Xvi manual

12. When is a SMU necessary and are there any alternatives?

A SMU (Safety Motion Unit) is necessary when the machine needs to have functional safety guidelines according to TÜV. With the SMU all functions are integrated into the XENAX® Xvi75V8 this saves space, wires and space.

SMU Safety Integrity Level 2:

STO: Safe Torque Off (Immediate shut-down of the output stage.)

SS1: Safe Stop 1 (Stop followed by shut-down of the output stage)

SS2: Safe Stop 2 (Stop while remaining in stop position)

SLS: Safely Limited Speed (Safe Speed if limited Speed is exceeded SS2)

Akternativly the STO can be made with a safe power off (switching off the power supply) or the XENAX® Xvi pin 9.

13. Can I install the optional modules (Fieldbus / SMU) by myself?

The SMU modules are assembled and tested strictly according to TÜV specifications, so all safety functions are guaranteed. The fieldbus modules undergo a 100% functionality check, after mounting on to the XENAX® Xvi with appropriate PLC during our assembly process.

That is why our option modules cannot be retrofitted by the customer.

14. Which linear motor axes support Forceteq®?

Forceteq® runs without an additional force sensor. Forceteq® integrated into the XEANX® Xvi, which are available with all linear and rotary motor axes. The difference between the individual axis types is the resolution, accuracy and minimum force.

| Linear Motor | Force Constant | Minimally Measurable Force | Resolution |

| INTAX® TX F08 | 1N ~ 20 * 10 mA | 0.5 N | 0.25 N |

| LINAX® Lxc F08 | 1N ~ 32 * 10 mA | 0.5 N | 0.25 N |

| LINAX® Lxc F10 | 1N ~ 28 * 10 mA | 0.5 N | 0.25 N |

| ELAX® Ex F20 | 1N ~ 12 * 10 mA | 0.5 N | 0.25 N |

| LINAX® Lxc F40 | 1N ~ 11 * 10 mA | 1.0 N | 0.5 N |

| LINAX® Lxu Lxs F60S | 1N ~ 10 * 10 mA | 10.0 N | 5.0 N |

| LINAX® Lxs F120 | 1N ~ 6 * 10 mA | 16.0 N | 8.0 N |

| Rotativ-Motor ROTAX® | Torque Constant | Minimally Measurable Torque | Resolution |

| Rxvp 28-6T0.04 | 10mNm ~ 23 * 10 mA | 6 mNm | 3 mNm |

| Rxhq 50-12T0.3 | 10mNm ~ 8 * 10 mA | 20 mNm | 10 mNm |

| Rxhq 110-50T1.5 | 10mNm ~ 2.5 * 10 mA | 60 mNm | 30 mNm |

| Rxhq 110-50T4.0 | 10mNm ~ 1.4 * 10 mA | 100 mNm | 50 mNm |

16. How do I use Forceteq® with a PLC?

The Forceteq® functions are available with the cyclic-transferable commands (PDO).

I_Force Actual LINAX®/ELAX®, 2005h

Limit I_Force, 6073h

The following SDOs are available :

Direct commands, no parameter, 5000h

Read parameter, XENAX®, 5001h

Write parameter, XENAX®, 5002h

Read / Write parameter XENAX®, 5003h

Further information can be found in our documentation CANopen Ethernet Protocol.

17. Can I control a LINAX®, ELAX® or ROTAX® with a "third party controller"?

Our experience in the past with third-party controllers has repeatedly shown difficulties and failures. Due to faulty commutation angles or incorrect parameterization, the motors ran with poor efficiency and overheated. Our axes were considered faulty in this context.

Since we recommend no third-party controllers, these problems are off the table.

Die XENAX® Xvi servo controllers are specially designed for our direct drive aces. Many benefits are only available with them

Advantages oft he XENAX® Xvi with our axes:

- Identification and communication with the connected axis

- Automatic parametrization

- Redundant temperatur monitoring with a Sensor inside the coil and I2T.

- Reference drive to detect the absolut position.

- Precise calculation of the commutation angle, important for high efficiency of the motors.

More Features:

- Patented Forceteq® functionality to record, limit and messure forces without an external force sensor

- Connection to all common PLCs such as EtherCAT, Profinet, Ethernet/IP, Powerlink or CANopen via real-time Ethernet bus. Tutorials with example for every PLC available to download from our website.

- Optional functional Safety (STO, SS1, SS2, SLS) TÜV certifizied SIL 2, PL d, Cat.

BACK TO TOP

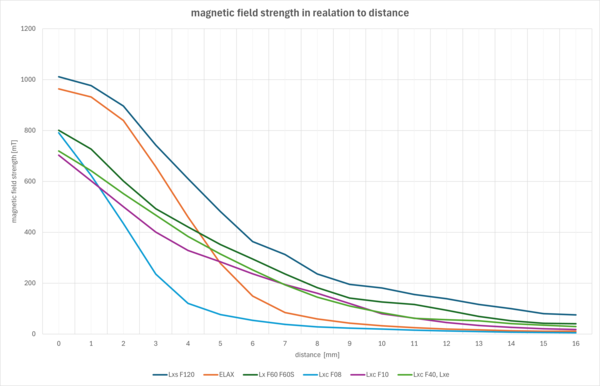

18. Magnetic effect of the linear motor axes?

The permanent magnets of the linear motor axes generate magnetic fields where they can act directly to the outside. On our LINAX® Lxc and ELAX® Ex linear motor axes, this is on the carriage bottom when the carriage is extended. There is no magnetic field on the upper side of the carriage because the iron.

For the Lxs / Lxu, the magnetic fields are on top of the baseplate. Here, the permanent magnets are act directly to the outside. Likewise, there is no magnetic field on the underside of the base plate because of the iron.

Magnetic field strength [mT] in relation to the distance from the magnets